MANUFACTURING A ROUGHER ENDMILL

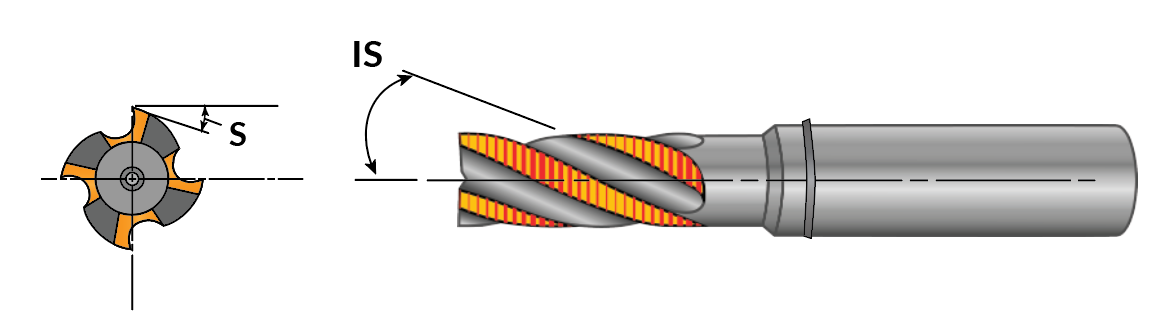

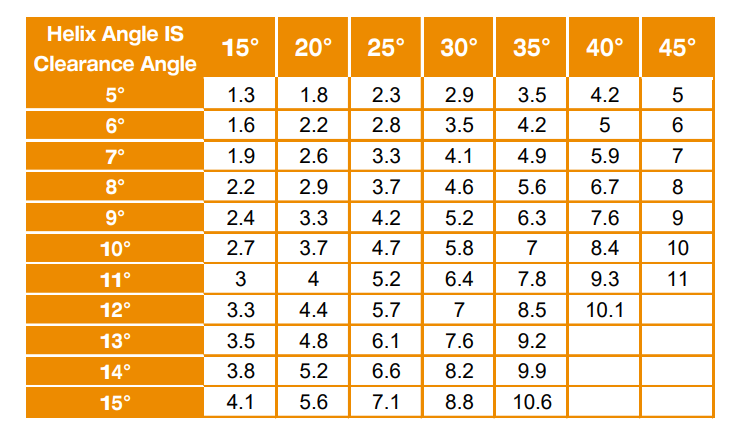

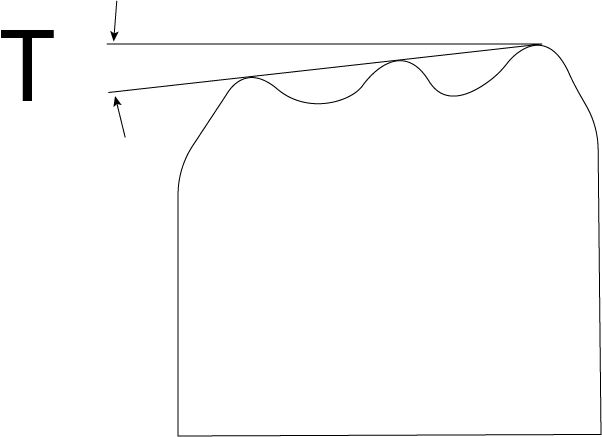

To grind a rougher endmill it requires the use of a profiled grinding wheel with a 1S1 FEPA shape. This profile grinding wheel must also be produced with an angle, "T" in harmony with the geometry of the rougher endmill or chip breaker tool. The grinding wheel parameters needed to correctly profile the wheel are:

IS = Helix angle

S = Clearance angle

The following table shows the values for the most common used angles, given by helix angle and the clearance angle above mentioned (IS and S), will provide the "T" value, see chart below.

The following is a chart with most common profile wheels. Soon blank wheels with a 14A1, and 1A1 shape, and bore 31.75mm [1-1/4"] will be in stock and ready to be profiled within days. Please contact us for any custom or special profile form you would like us to manufacture for you. Remember, we at Mirka are here to help you perform better with Cafro super abrasives.

|

If you have any questions about carbide cutting tools, end mills, drills, etc. be sure to reach out to us @ sctools.co/Home or call us at (877)737-0987. We help you machine better! |

Comments (0)